Contract Converting Services

Our Contract Converting Capabilities

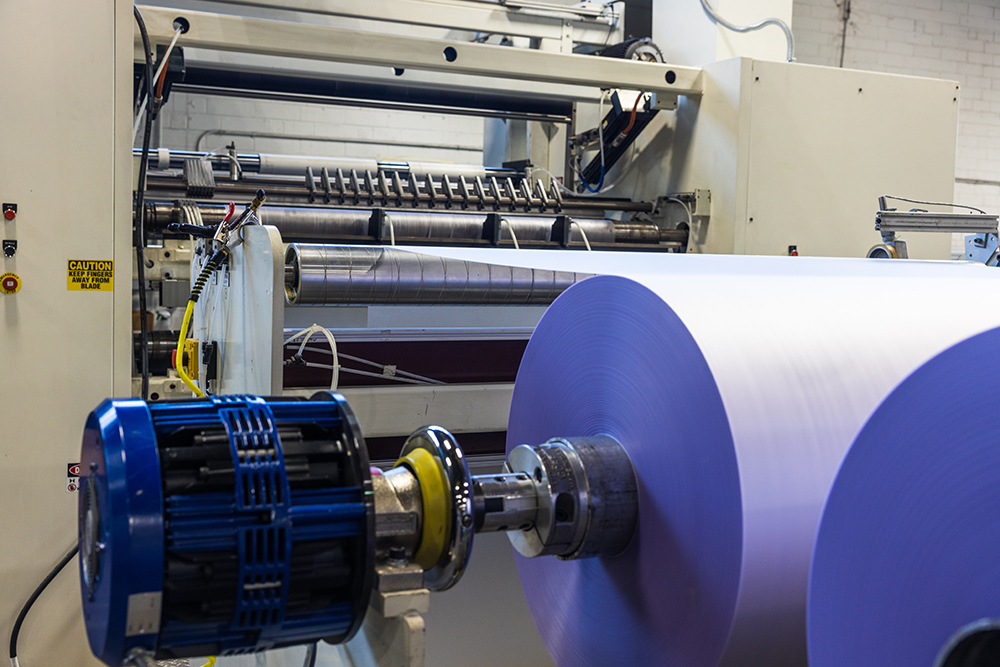

Our team is proud to boast a broad range of contract converting capabilities suitable for virtually any project need. Spanning a broad range of sizes, diameters, and materials, our toll converting capabilities know no bounds. We have experience converting everything from nylon for flags to fabric for bedding; printed and non-printed vinyl signage to film sandwich wrappers. Our converting capabilities proudly include:

Contract Slitting Rewinding Capabilities

We have capabilities to slit using the most common slitting method available, including:

- Materials: Non-wovens, wovens, vinyls, films, foams, laminated materials, most materials (speak with a service representative to learn more)

- Max Roll Width: 140”

- Max Unwind Diameter: 60”

- Max Rewind Outside Diameter: 40”

- Core Rewind: 3”, 6”

- Core Unwind: 3”, 6”, 12”

- Roll Weight: 5,000 lbs.

- Guiding: Line & Edge Guiding

Contract Slitting Methods

We have capabilities to slit using the most common slitting method available, including:

- Razor Slitting

- Score Slitting

- Shear Slitting

- Hot Knife Slitting (Fixed & Round Blade)

- Perforating

- Laser Slitting (Testing Only)

Foam Slitting

- Max Roll Width: 74”

- Max Roll Diameter: 60”

- Slit Widths: ½” (Razor Slitting) min.

Contract Sheeting

- In-line Slitting

- Roll Width: 92”

- Roll Diameter: 40”

- Roll Weight: 1,600 lbs.

- Sheet Length: Infinite

Special Packaging

- Custom Boxing & Casing

- Roll Separating

- Roll & Case Labeling

- Bagging

Slitting Services

As part of our contract converting solutions, Peak Slitting and Converting proudly offers slitting and rewinding services to manufacturers nationwide. Our state-of-the-art equipment efficiently converts rolls of various materials across a wide range of industries, from aerospace to healthcare.

With a long standing partnership with a top manufacturer of custom slitter rewinders in the United States, we have an in-depth understanding of the process and our clients’ needs. With our advanced equipment and decades of converting experience, we specialize in challenging projects, whether it’s handling unique materials or dealing with short lead times.

Why Trust Peak for Slitting and Rewinding Services

Peak has been in the business of slitting and rewinding for over 30 years offering contract slitting services to businesses. Here’s why so many manufacturers trust Peak when they need to outsource their converting needs.

- Partnerships with the machine manufacturers: Our team of experts not only understands the process of slitting and rewinding, but they also partner with the same individuals who design and build our state-of-the-art slitter rewinders. This gives us an in-depth knowledge of the machinery and allows for efficient conversion processes.

- Logistical support: We are set up for shipping and receiving of your finished goods and provide just-in-time delivery.

- State-of-the-art equipment: Our fleet of slitter rewinders is equipped with the latest technology and features, enabling us to handle even the most challenging materials and projects.

- Precision: Our machines are designed for precise slitting and rewinding, ensuring your final product is of the highest quality. We understand the importance of accuracy and reliability, so all of our output is subject to a rigorous quality control process.